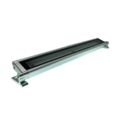

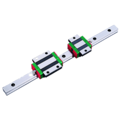

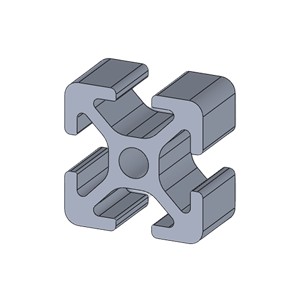

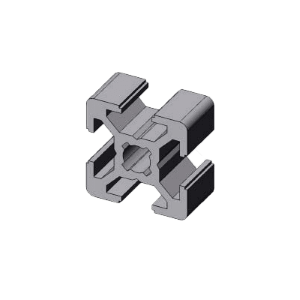

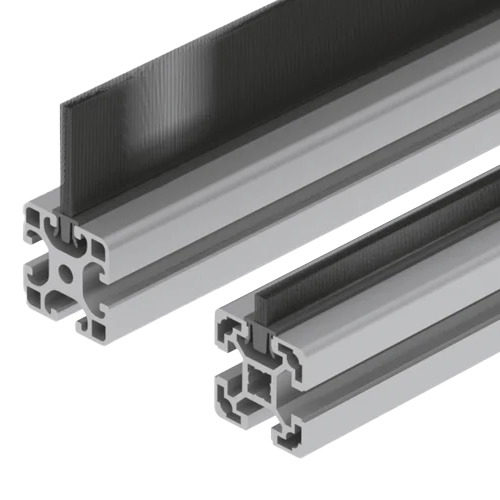

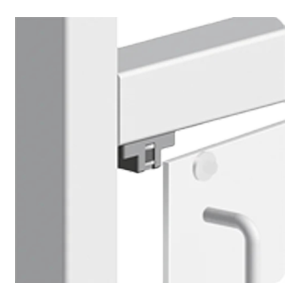

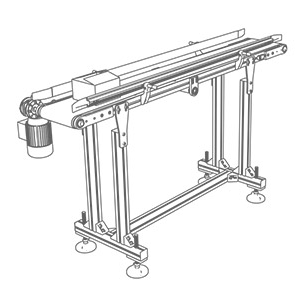

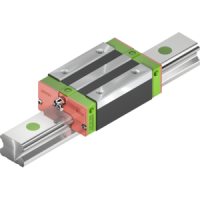

5.1.2 EG guidance system

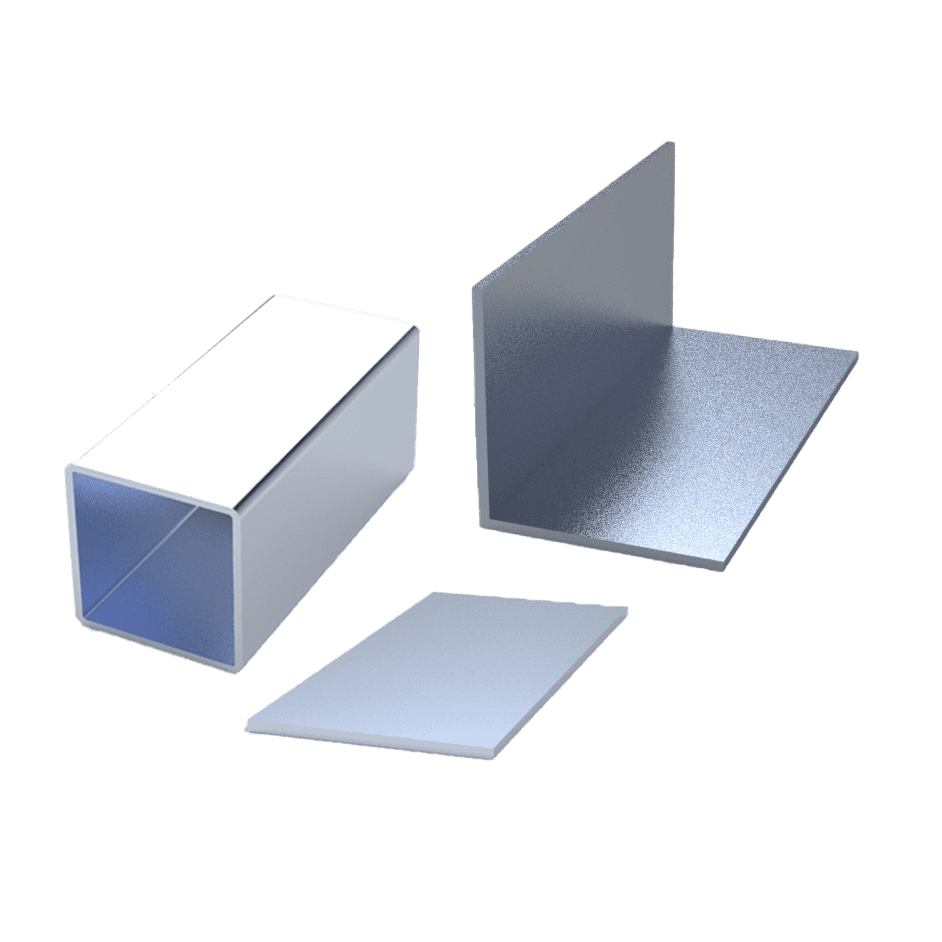

Range of EG linear guides

You can find our range of EG linear guides here:

- Linear guides EG 15 type

- Linear guides EG 25 type

Characteristics:

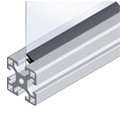

Linear guide from 500 mm to 3,000 mm

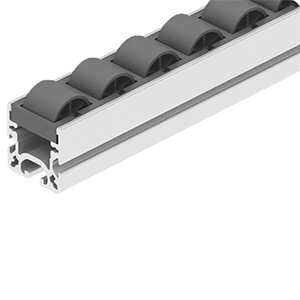

Recirculating ball bearing sliders

Lubrication and dust protection

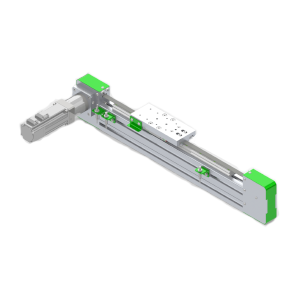

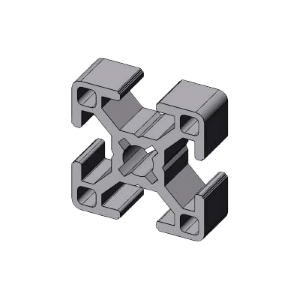

What is an EG linear axis?

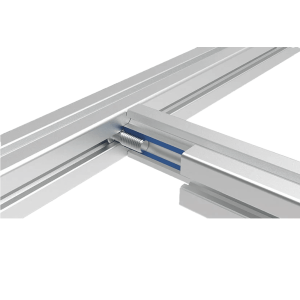

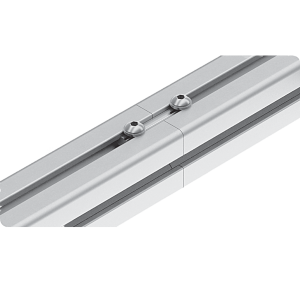

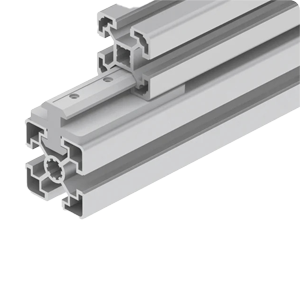

A linear guide is composed of a guide rail as well as a ball or roller bearing raceway which create a linear movement with an extreme precision. With the bearing components, it makes a precise linear movement.

Its technology reduces friction (up to 50 times less) and facilitates the system to move to extend the life of the system by reducing wear.

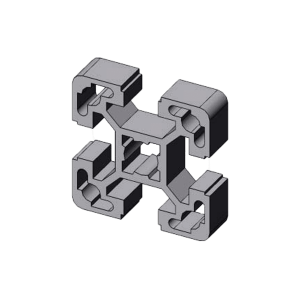

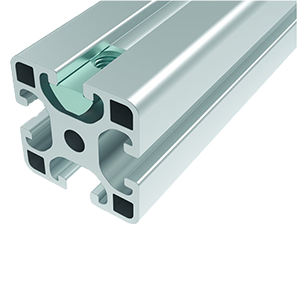

Linear guides on profile rails make it easier for automatised systems to move. Mounting on profile rails is simple and can be realised on any axis (horizontal and vertical). The rail will guide the movement and simplify it.

Using EG linear axes

EG linear guiding series has a high load and rigidity capacity. We use it in the automation field especially, but also for high-speed transportation and limited spaces.

In other cases, other ranges exist such as MG guiding, made for miniature technologies.

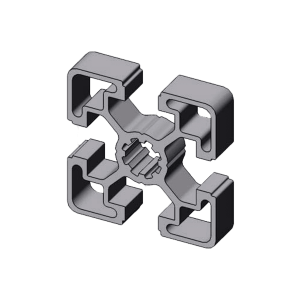

Choosing a linear guide axis

To choose an EG linear guide, you need to know several elements: the required moving distance, the maximum space and the height work, but also the load to move as well as the precision required.

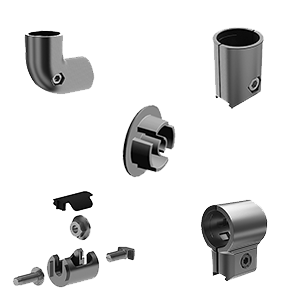

You can find:

Manual linear axes → guided movement with precision, reduced wear and effort and manual intervention.

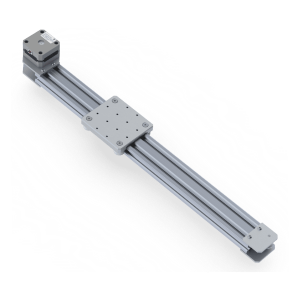

Ball screws and screw-nuts linear axes→ high movement precision, high load capacity. The assembly is made precisely.

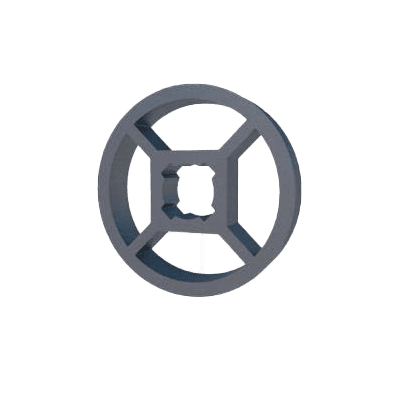

Pulley and belt linear axes→ easy assembly, high movement and acceleration precision.

Rack and pinion axes→ robust and easy to put in place on long lengths.