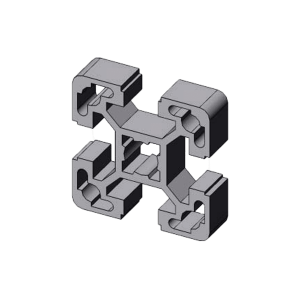

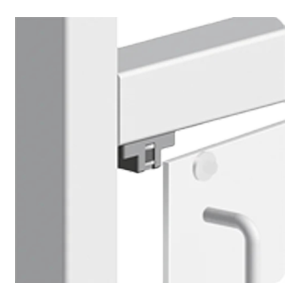

1.1.2 I3 IMO PLC

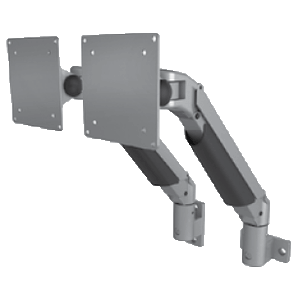

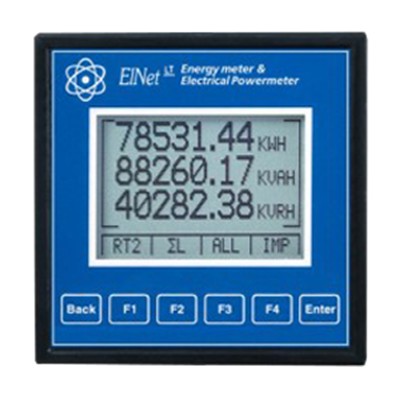

PLC I3 IMO with screen

We offer you a range of programmable logic controllers IMO-branded, including a series of PLCs with touch screen.

As the development of applications is on the same software (i3config) for the PLC programme and for the graphical interface, the gain in time for the PLC programme development is huge.

EASI-Spare guides you in your industrial automation projects.

|

|

|

|

Engineering department in automation →

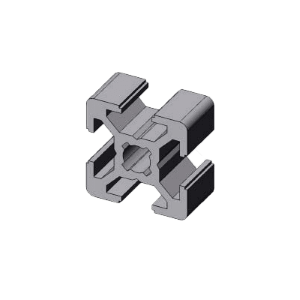

Programmable Logic Controller (PLC)

PLCs are used in the industrial sector to command systems for electrical installations. They are used for automating processes (machine control system) or for controlling robots.

The operation of an industrial PLC

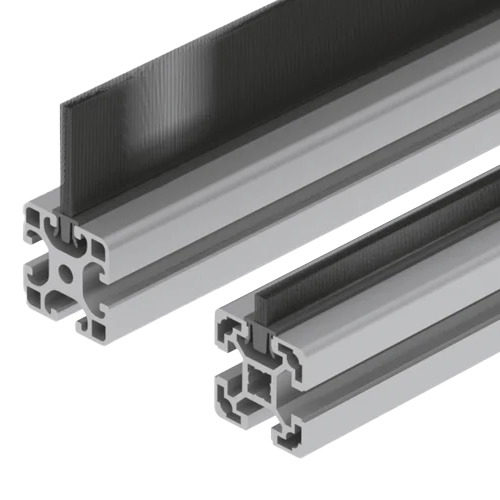

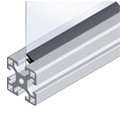

A PLC is composed of:

- - A microprocessor or CPU (Central Processing Unit)

- - A memory where the programme is stored

- - Physical I/O modules

- - A supply generally in 24V

The micro-PLC receives data via its inputs, that are then executed by the processor which put the programme into effect. The result is finally delivered by the outputs of the PLC.

Programming languages for PLCs

5 programming languages for PLCs are defined by standard IEC 61131-3:

- - LD (Ladder Diagram): very close to an electrical diagram, which makes it easily understandable.

- - IL (Instruction List): low level language and resembles assembly.

- - FBD (Function Block Diagram): graphical language

- - ST (Structured Text): high level language, block structured

- - SFC (Sequential Function Chart): visual programming language. It enables to code GRAFCET.

PLCs have several advantages. They are robust and sturdy (temperature resistant). They are also responsive in the implementation of the information received. Finally, the PLC is autonomous: once the programme is realised and integrated, the cycle starts.

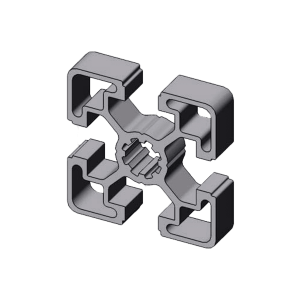

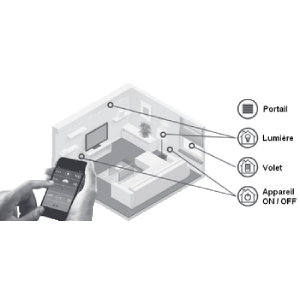

What is the purpose of a nano-PLC?

A nano-PLC enables to automate processes such as pump monitoring systems or tank monitoring systems (heating time and temperature). This is possible thanks to sensors or temperature controllers.

PLCs are also used for monitoring freight elevators, lifts or traffic lights.

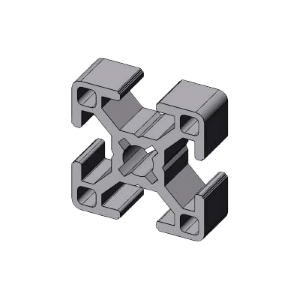

IMO I3 range has the advantage to integrate a touch screen and the industrial PLC in the same box, with the same programming software.

.png)